D I Y contact / hydro mic construction

Building a contact mic is not only a great way to become familiar with the electronics of sound (which is what it was for me) but also a source of opening up possibilities in field and music recording. Piezo plates function by capturing vibrations through solid and liquid states: revealing new sonic layers to even the most mundane acoustic events. The 27 mm piezo plates i used here are quite solid, lacking perhaps in deep bass frequency responses but still useful for glimpsing hidden sound worlds. If you’ve ever thought about it but didn’t know where to start, consider these step by step instructions. A massive thanks to resources from Angus Tarnawksy, Florence-Delphine Roux, and this helpful article from Felix Blume which I followed closely but slightly adjusted for my needs.

list of materials per ONE mic

- bottle cap (preferably from Tradition brand juice)

- TS 1/4 cable with exposed + / – wire end

- 27 mm piezo plate

- electrical tape

- silicone caulking

- copper filament (0.05mm x 10mm x 1000mm)

- copper paper (3500mm x 150mm x 0.01mm)

- washers or bolts (for adding weight)

- plastidip liquid rubber

recommended tools

- drill with 1/8” drill bit

- soldering iron with tin wire (0.8 gauge is great)

- exacto blade

- clothes hanger

- scissors

- wire strippers if needed

STEP 1: prepare the cap

I loved using these tradition brand caps because of their coincidentally perfect size for housing the piezo and copper filament.

All you need to do to prepare the cap is:

1) cut an X with the exacto knife and carefully carve the cap’s surface into a circle, leaving a roughly 1.5 cm hole.

2) use your drill and 1/8″ drill bit to bore two small holes on the lateral side of the cap.

3) next, measure the correct amount of copper ribbon needed to coat the inner circumference of the cap, leaving space for the newly bored holes. Place your piezo inside the cap, shiny side down:

STEP 2: soldering

1) this is it y’all! make sure to warm up you soldering iron if it isn’t already. Usually 300-350 degrees Celsius is the sweet spot for the iron’s temperature. Be careful here! the iron’s rod and tip will extremely so use caution where you leave the iron and how you handle it.

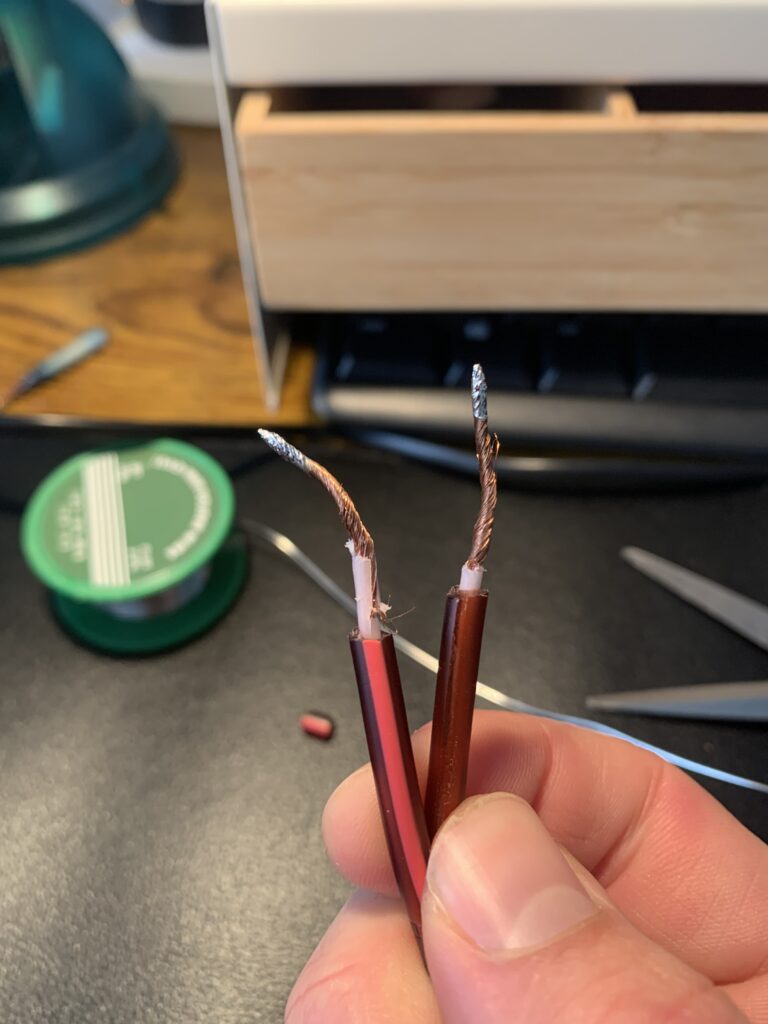

take you exposed +/- wire, sliding the black and red parts exclusively through their own hole on the lateral side of the cap. once through the hole, position them so that the red wire (+) is over the centre ceramic plate, and the black wire (-) is over the shining metal border. The piezo will now complete this circuit!

2) with a hot iron, press the tip on the areas of the piezo you will stick the wire to. The soldering usually works better when the surface is warmed up.

3) press the tip of your soldering iron to the tin wire (STAY AWAY FROM LEAD – IT MELTS EASILY BUT IT IS TOXIC), then bring the tip of your iron to the piezo contact points.

gracefully bring in the tin wire to the iron tip / piezo / wire contact points : maximizing the heat transfer, making for a “cold-free”, easily manipulated soldering job

NOTE: if the soldering does not work super well, it might be because the iron is too cold. Be patient, let it heat up nice and warm before soldering.

STEP 3: fill the cap

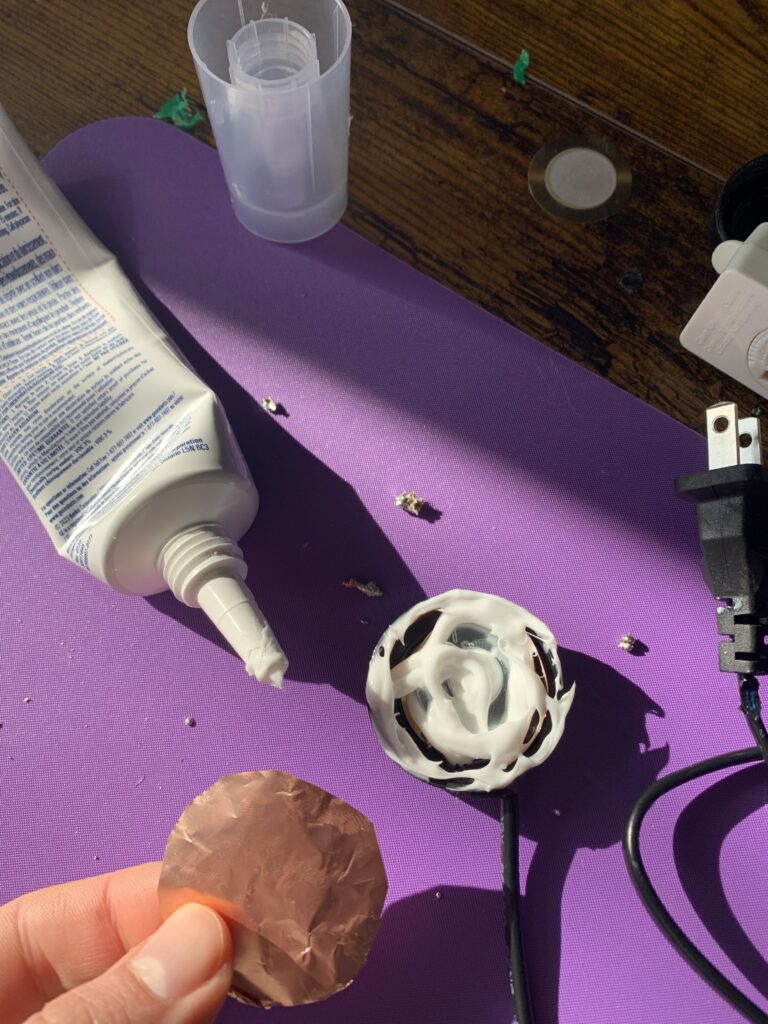

it’s time to fill the capsule with silicone and washers to weigh down your mic!

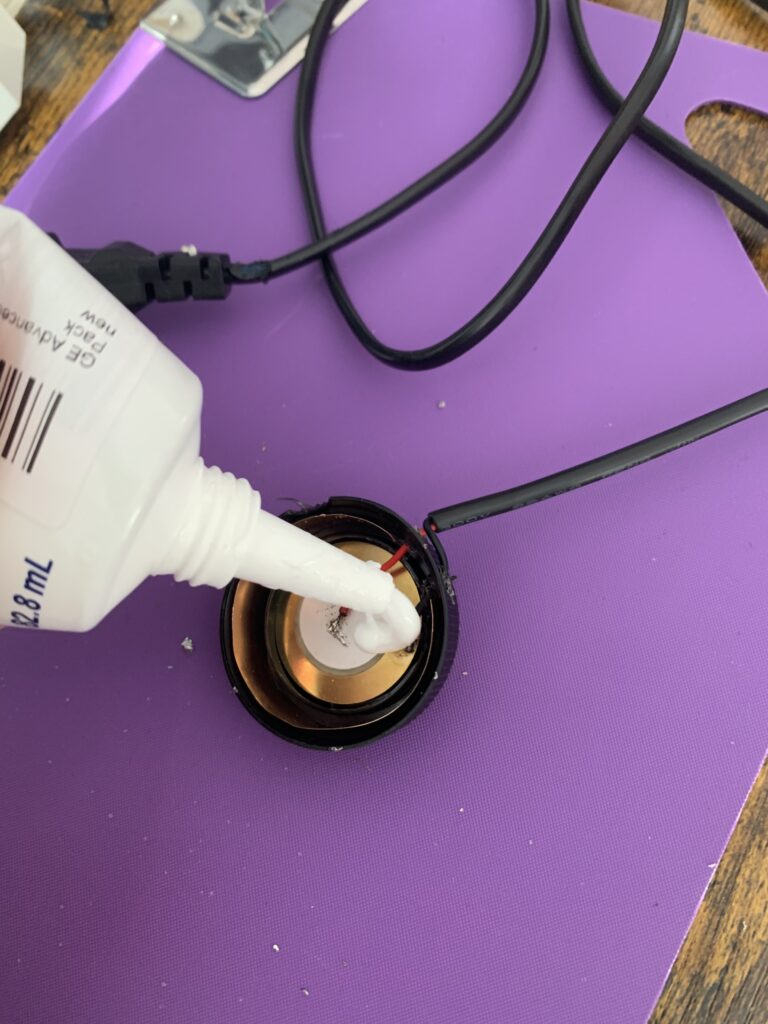

1) squirt in some silicone caulking. I also like to pipe it around the rim of the cap to make for a nice tight seal.

2) place one washer or a few bolts to add weight to the cap

3) cut a cap-sized circle from the copper paper and press it atop the silicon-filled cap, acting almost like a cap for the cap. All this copper helps isolate the electronics within from other electromagnetic interferences, which means a cleaner signal for your mic.

4) you can rest now. let the silicone dry and glue the whole cap and components within together. Come back tomorrow to finish your mic!